Carbon Steel Conveyor Belt Galvanized, Hot Zinc Plated, Teflon Covered, PVC Coated

General Information:

Metal belts for conveying and transmissing can be made of Mild steel, low carbon steel or high carbon steel materials. Zinc coating optional for anti-corrosion treatment.

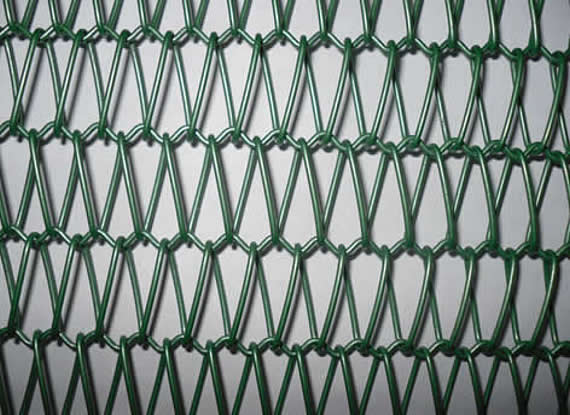

Structure Type: Spiral mesh belt, flat flex mesh belt, balanced weave, hinged steel plate, rhombus mesh belt, honcycomb mesh belt.

Carbon steel conveyor belt mesh surface treatment: Galvanizing, Hot dipped zinc plating, Teflon / PTFE coating, PVC coated.

Choose finishes for carbon steel mesh belts according to specific requirements:

- Galvanized steel conveyor belts are known for durability and resistance to corrosion at less cost compared with hot dipped zinc coated belts, however, the mesh surface can wear over time, especially under heavy loads or abrasive conditions.

- Hot dipped zinc-plated steel conveyor belts coated with a thicker layer of zinc, offer enhanced corrosion resistance compared to regular galvanized mesh belts, providing longer-lasting protection in harsh environments.

- Teflon-coated metal conveyor belts are ideal for high-temperature applications and situations requiring non-stick surfaces, offering excellent heat resistance and low friction, less robust in mechanically abrasive conditions as galvanized or zinc-plated belts.

- PVC coated steel conveyor belt can provide better resistance against certain chemicals and environments where a non-reactive surface is needed, compared with galvanized mesh belt.

Carbon steel conveyor belt treated with zinc coating is the economic metal belts for many industrial draining and packing assembly line applications. Compared with stainless steel mesh belt, carbon steel conveyor belt mesh costs less.

Benefits of Using:

Open Area - up to 85% open area, most open area in the industry;

Cleaning - Easy to clean;

Minimal Contact - open area provides little contact with belt;

Tight Transfers - Small products to transfer easily;

Affordable low cost;

Labor cost saved.

The steel mesh carrying belt can be composed of round wire or crosswire. The wire is from spring steel, carbon or stainless. It can also be made from flat spirals, wound with the same orientation from round section wire. The spirals are interlaced. The belt has no connecting cross rods and made the square shape mesh approximately.

Common style applied for carbon steel belting production: Balanced weave, chain drive, slat plate, perforated screen, honeycomb, ladder mesh.

The steel mesh belting can be made of round wire or flat wire.

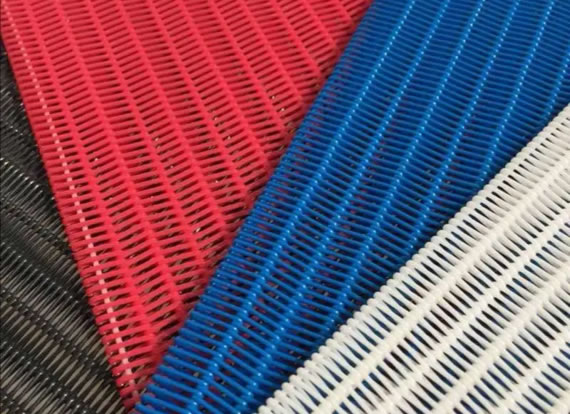

Carbon steel flat mesh belt: Low carbon steel conveyor belt galvanized finish, bright surface, smooth belt

PVC Coated Carbon Steel Conveyor Belt Mesh:

Belting Products

Black Metal Conveyor Mesh Conveyor Wire Mesh Belt 310 Washer Conveyor Belt Cooling Conveyor Belt Chain Rod Conveyor Belt Perforated Metal Conveyor Belt Slat Conveyor Belt Steel Sprockets Metal Chains Dryer Chain Link Conveyor Belt Eye Link Wire Mesh Conveyor Belt 316 SS Conveyor Belt Flat Flex Wire Conveyor Belt Flat Woven Steel Mesh Belt Duplex Mesh Conveyor Belt Balanced Weave Wire Mesh Conveyor Belts Chevron Mesh Belt Round Wire Spiral Woven Belt with Rod Reinforcement Close Mesh Woven Wire Conveyor Belt Wire Loop Conveyor Belt Chain Driven Metal Conveyor Belt Stainless Steel Wire Mesh Conveyor Belt Carbon Steel Conveyor Belt Food Grade Conveyor Belts for Drying application Heavy Duty Flat Wire Conveyor Belt Honeycomb Wire Mesh Structure Metal Conveyor Belts Woven Wire Belting for Furnace and metallurgy Food Baking Belt Double Rod Reinforced Chain Wire BeltAdd: 31 Yinwang Road, Wire Mesh Development Zone, Anping, Hebei, China

Tel: 0086-318-29232184 Fax: 0086-318-29232184

Email: conveyor-belt@wireconveyorbelt.com