304 and 316 Stainless Steel Wire Mesh Belts for Sintering Furnace

General Introduction: Sintering Furnace Belt is a kind of metal mesh conveyer belt made of Stainless Steel SUS304 or SUS316 Strips and Rods. It offers excellent property against heating and suitable for high temperature working conditions, such as furnace and metallurgy. Also known as FURNACE BELTS, Sintering Belt.

Metal Conveyor Belt for Furnace - AISI 310 SS Grade

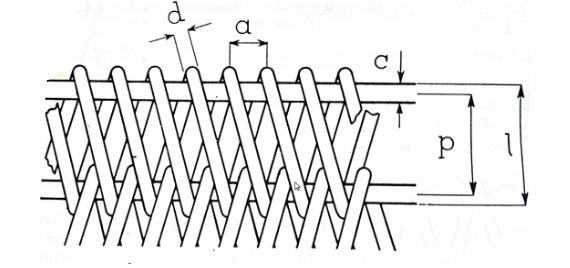

Mesh belt drawing:

Metal Conveyor Belt with the following specifications:

Working Temperature: 1000°C

Wide: 0,60 m.

Long: 65 m

Spiral Wire Pitch (a): 7,5 mm

Wire numbers: 79 wires along the conveyor belt width.

Internal Spiral Wire Spacing (l): 30 mm

Spiral Wire Diameter (d): 3 mm

Connectors Wire Diameter (c): 5 mm

Distance between transversal wires(p): 25 mm

Material: AISI 310 / AISI 314

Furnace Conveyor Belt - AISI 314 Grade

The furnace belts can be used with conveyers as mentioned below or custom specifications:

a) Conveyer Length : 28 Mtrs.

b) Conveyer Width : 450 mm

c) Conveyer Thickness: 6 mm

d) Operating temp. of the furnace : 1000 Deg.

f) Load on belt : 10 Pound / Ft

Anti-Heat Stainless steel wire mesh belts are used in typical processing of metals such as sintering, tempering, quenching and cooling in metallurgy.

Popular Weave Types:

Double balanced weave

Duplex weave

.

General specifications of ss conveyor belt for quenching and sintering furnace in metallurgy:

Material:SUS 202,304,310,316,316L

Wire diameter: 0.8mm ~4mm

Belting Products

Black Metal Conveyor Mesh Conveyor Wire Mesh Belt 310 Washer Conveyor Belt Cooling Conveyor Belt Chain Rod Conveyor Belt Perforated Metal Conveyor Belt Slat Conveyor Belt Steel Sprockets Metal Chains Dryer Chain Link Conveyor Belt Eye Link Wire Mesh Conveyor Belt 316 SS Conveyor Belt Flat Flex Wire Conveyor Belt Flat Woven Steel Mesh Belt Duplex Mesh Conveyor Belt Balanced Weave Wire Mesh Conveyor Belts Chevron Mesh Belt Round Wire Spiral Woven Belt with Rod Reinforcement Close Mesh Woven Wire Conveyor Belt Wire Loop Conveyor Belt Chain Driven Metal Conveyor Belt Stainless Steel Wire Mesh Conveyor Belt Carbon Steel Conveyor Belt Food Grade Conveyor Belts for Drying application Heavy Duty Flat Wire Conveyor Belt Honeycomb Wire Mesh Structure Metal Conveyor Belts Woven Wire Belting for Furnace and metallurgy Food Baking Belt Double Rod Reinforced Chain Wire BeltAdd: 31 Yinwang Road, Wire Mesh Development Zone, Anping, Hebei, China

Tel: 0086-318-29232184 Fax: 0086-318-29232184

Email: conveyor-belt@wireconveyorbelt.com