Chevron weave Conveyor mesh belt for Baking Band - Biscuits Baking, Drying in Food Industry, Sorting small parts and stuffs - Flat wire or Round Spiral Wire

General Introduction:

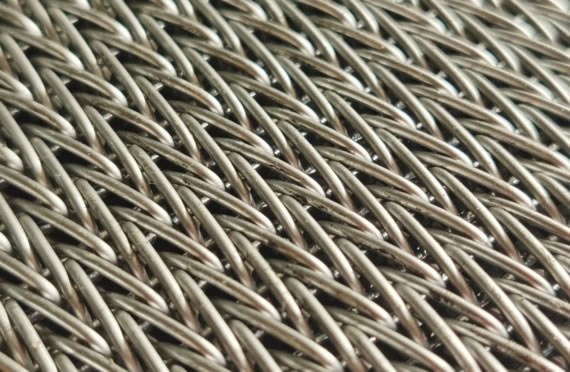

Chevron mesh belt is a balanced spiral mesh belt that has multiple spirals and cross rods per pitch in compound balanced weave to form a chevron or V mesh structure. Also known as V shaped conveyor belt or Compound Balanced Weave Conveyor Belt.

Chevron weave mesh belt has thick wires connected to each other to form a close mesh structure.

Compound Balanced Weave Conveyor Belts can be supplied with welded edge, chain edge, side guard edge.

Wire Materials Choices:

304, 302, 316 stainless steel. Other materials are available upon request.

Wire sections: Round wire or flat wire

Compared with balanced mesh conveyor belt:

Compound balanced v mesh is similar to a balanced weave, but it has smaller opening and far denser weave, closer and flatter mesh.

Chevron mesh also offer higher tensile strength resulted from multiple spirals and cross rods on each pitch, this mesh belt can supply higher tensile strength than common balanced woven conveyor belt.

Stainless Steel Compound Balanced Weave Chevron Mesh Conveyor Belt

Compound Balanced Weave Mesh Conveyor Belt in Stainless Steel 304 offers durability and a stable conveying surface, excellent corrosion resistance and longevity, suitable for biscuits baking and harsh industrial environments when product stability and hygiene are critical.

Applications: Heat Treatment, Food Processing, Pharmaceutical manufacturing and more.

Advantages:

- Durability: Combines the robustness of Stainless Steel 304 with a sturdy weave.

- Low Maintenance: Its durable nature leads to reduced upkeep costs.

- Versatility: Suitable for a wide range of products and industries.

- High-temperature resistance: SS compound weave conveyor belt is made of high-quality materials, stainless steel and nickel alloy steel, offering excellent temperature resistance performance.

Structure and Design

- Weave Type: The compound balanced weave consists of a series of tightly-woven, interlocking spirals. Unlike a standard balanced weave, the spirals in a compound balanced weave are closer together, which provides a denser, flatter surface.

- Material: Typically made from metals like stainless steel or carbon steel, these belts are chosen for their durability and resistance to various environmental factors.

This type of wire mesh belt provides the highest tension. Smooth belt surface is appropriate for transferring unstable items.

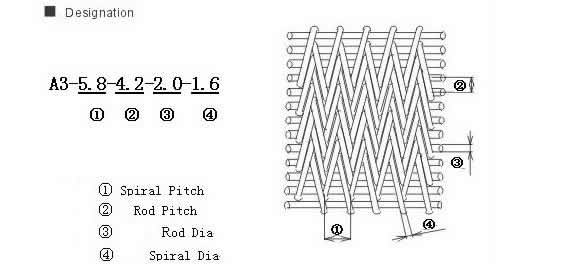

Structures:

The left-wound right-wound spirals are fitted tightly together alternately and jointed with straight rods. A4 uses 4 rods for one spiral to joint. A3 uses 3 rods for one spiral to joint.

Advantages:

1.Since the surface is flat and smooth, the belts can carry small items and unstable products.

2.The allowable tension is high, so that heavy load can be transported.

3.The chevron design wire belt has high strenghth against pressure, it can be used for processing under pressure.

4.Can be used at high temperature.

5.The belt provides uniform heat transfer across the belt.

6. Baffles can be added to chevron mesh belt for efficient sorting and conveying products.

Belting Edge Treatment:

The edge can be welded, clinched, chain link or chain plates.

Samples of Metal Belting Conveyor, Chevron Wire Structures, Dense Mesh Flat Surface

Chevron or V Shape Weave Conveyer Mesh Strips - Stainless Steel

Stainless Steel belt supplied to industrial machinery and equipment producer in Latvia

Belt Width 1000mm

Belt length 16 m

Supplied with driver sprockets d ~150mm.

Application – The conveyor belt is used as dryer for animal and poultry dietary food supplement production from liquid to dray fraction.

In replacement of simple Stainless Steel Net as belt with 1mm opening

V Mesh Biscuit Baking Conveyor Belt

Due to its unique structures, this closely woven wire belt it is suitable for conveying and carrying of small parts and stuffs, for biscuits production line, for example.

When used as Biscuit Baking Belt, v mesh belt is known as Rolled Baking Band, or Z Belts for Z shape of the flattened spirals.

Belting Products

Black Metal Conveyor Mesh Conveyor Wire Mesh Belt 310 Washer Conveyor Belt Cooling Conveyor Belt Chain Rod Conveyor Belt Perforated Metal Conveyor Belt Slat Conveyor Belt Steel Sprockets Metal Chains Dryer Chain Link Conveyor Belt Eye Link Wire Mesh Conveyor Belt 316 SS Conveyor Belt Flat Flex Wire Conveyor Belt Flat Woven Steel Mesh Belt Duplex Mesh Conveyor Belt Balanced Weave Wire Mesh Conveyor Belts Chevron Mesh Belt Round Wire Spiral Woven Belt with Rod Reinforcement Close Mesh Woven Wire Conveyor Belt Wire Loop Conveyor Belt Chain Driven Metal Conveyor Belt Stainless Steel Wire Mesh Conveyor Belt Carbon Steel Conveyor Belt Food Grade Conveyor Belts for Drying application Heavy Duty Flat Wire Conveyor Belt Honeycomb Wire Mesh Structure Metal Conveyor Belts Woven Wire Belting for Furnace and metallurgy Food Baking Belt Double Rod Reinforced Chain Wire BeltAdd: 31 Yinwang Road, Wire Mesh Development Zone, Anping, Hebei, China

Tel: 0086-318-29232184 Fax: 0086-318-29232184

Email: conveyor-belt@wireconveyorbelt.com